Whether it is to ensure the normal operation of household appliances in our daily life or to assist in the precise control of complex machinery in the industrial field, the micro switch silently fulfills its mission. The following will discuss the working principle of the micro switch in depth through the form of questions and answers

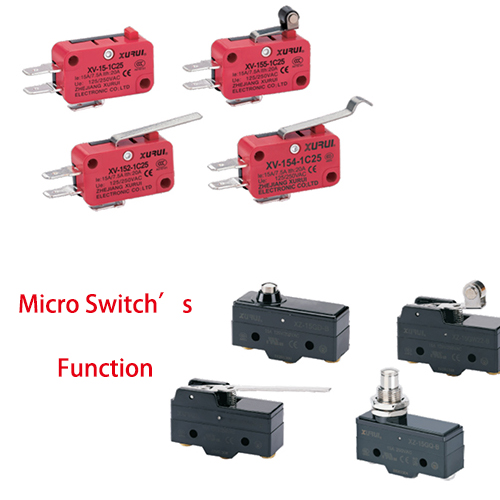

I. What is a micro switch?

A micro switch is a switch with a small stroke and is usually small in size. It is widely used in various fields such as electronic equipment, mechanical equipment, automobiles, and household appliances. It can be used to detect changes in physical quantities such as the position, pressure, and displacement of an object, and convert them into electrical signals, thereby realizing the control of a circuit or the transmission of signals.

II. What are the basic components of a micro switch?

♦A micro switch mainly consists of the following key parts:

Contact system: It includes stationary contacts and movable contacts. The stationary contacts are fixed, and the movable contacts can make contact with or separate from the stationary contacts under specific conditions, thus realizing the conduction or disconnection of the circuit. For example, in some micro switches, the movable contact is connected to a movable spring blade.

♦Operating mechanism: Common forms include buttons, levers, rollers, etc. By applying an external force to the operating mechanism, it will cause displacement or deformation, which in turn drives the movable contact to act. For example, when a button-type operating mechanism is pressed, it will cause the internal components to move.

Spring system: Its main function is to provide a restoring force. When the external force is removed, the spring can return the operating mechanism and the movable contact to their initial positions, ensuring the repeatability and stability of the switch. For example, in some micro switches, a compression spring is used to achieve this function.

III. How does a micro switch work?

When an external force is applied to the operating mechanism of the micro switch (such as pressing a button, pushing a lever, or rolling a roller), the operating mechanism will be displaced or deformed. This change will be transmitted to the movable contact, causing the movable contact to overcome the resistance of the spring and approach the stationary contact until they finally make contact. At this time, the circuit is conducted and current can pass through the switch. When the external force disappears, the spring system comes into play, pulling the operating mechanism and the movable contact back to their original positions, and the movable contact separates from the stationary contact, disconnecting the circuit. For example, in an application where a micro switch is used to detect whether a door is closed, when the door is closed, it will press the lever of the micro switch, closing the internal contacts and conducting the circuit, and the relevant device (such as the door lock indicator light) will receive the signal that the door is closed. When the door is opened, the lever is no longer under force, and the spring disconnects the contacts, changing the signal.

IV. What are the characteristics of the working principle of a micro switch?

1.Fast response: A micro switch can respond to an external force in a very short time and achieve rapid closing or opening of the contacts. The response time can usually reach milliseconds or even shorter.

2.High sensitivity: Even a small change in the external force can be detected by the micro switch and converted into a change in the contact state. Its sensitivity can be adjusted according to different design and application requirements.

3.Good repeatability: Due to its structure and spring system design, under the same external force, the micro switch can repeatedly and accurately perform contact actions, ensuring the reliability and stability of its work. For example, in an industrial automation production line, frequently used micro switches can work stably to ensure the normal progress of the production process.