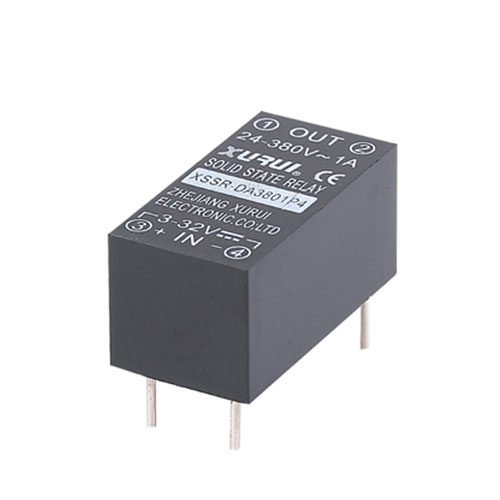

Solid state relays are "integrated" non-contact electronic switching devices consisting of integrated circuits and discrete components (check price|reference|preference). Since its introduction, it has replaced electromagnetic relays in many automatic control devices and is widely used in areas where electromagnetic relays cannot be used. However, electronic devices are susceptible to damage. How do you test a solid state relay? Let's take a look below.

Multimeter testing of solid state relays.

1. Measure the contact resistance.

Use multimeter resistance class to measure the resistance of normally closed contact and moving point, the resistance value should be 0; while the resistance between normally open contact and moving point is infinite, so you can distinguish which is normally closed contact and which is normally open contact.

2. Measure the coil resistance.

You can use a multimeter x10 to measure the resistance of the relay coil, so as to determine whether the coil is open.

3. Measure the suction voltage and current.

Find an adjustable regulated power supply and ammeter, give the relay a set of voltage input, and send the ammeter in the supply circuit to test. Slowly increase the supply voltage. When you hear the relay close, make a note of the closing voltage and current. For accuracy, you can try several times to get the average value.

4. Measure the release voltage and current.

Test as above. After the relay is sucked in, reduce the supply voltage one by one. When you hear the release of the relay again, write down the voltage and current at this time, and try several times to get the average value. Generally speaking, the release voltage of the relay is about 10-50% of the suction voltage. If the release voltage is too small, it will not work properly. This can threaten the stability of the circuit and make it unreliable. Now you know how to measure the quality of a solid state relay. You can find a multimeter to determine this.